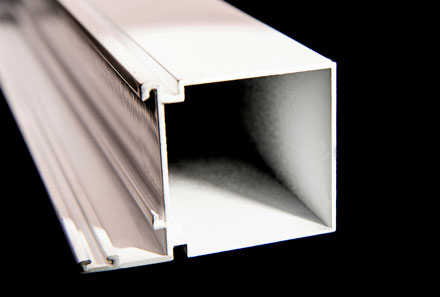

GENERALITIES ABOUT EXTRUDED ALUMINUM

Aluminum frames

For the extrusion of aluminum profiles, series 6xxx alloys are normally used. These use as alloying elements Mg (Magnesium) and Si (Silicon) in adequate proportion allowing them to be heat treatable.

These alloys have better formality, weldability, machinability and corrosion. They can also be molded and hardened artificially.

Tempering, in an aluminum alloy, is produced by a mechanical or thermal effect, creating structure, hardness, and diverse properties.

Aluminum, due to its properties, is one of the metals that is most used to produce varied and complicated types of profiles used mostly in metalwork and the transport industry. The alloy 6063 is the most used for architectural purposes.

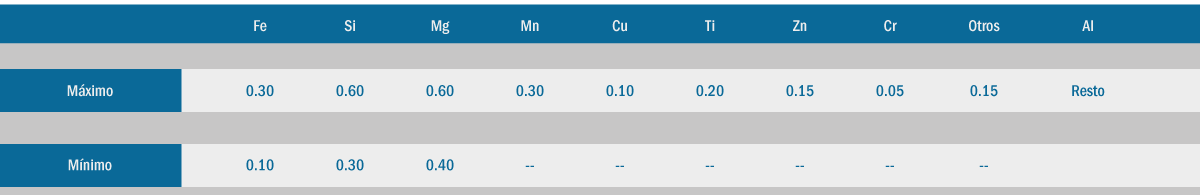

6063 or AlMgSi0,5 alloy

More generalized chemical composition:

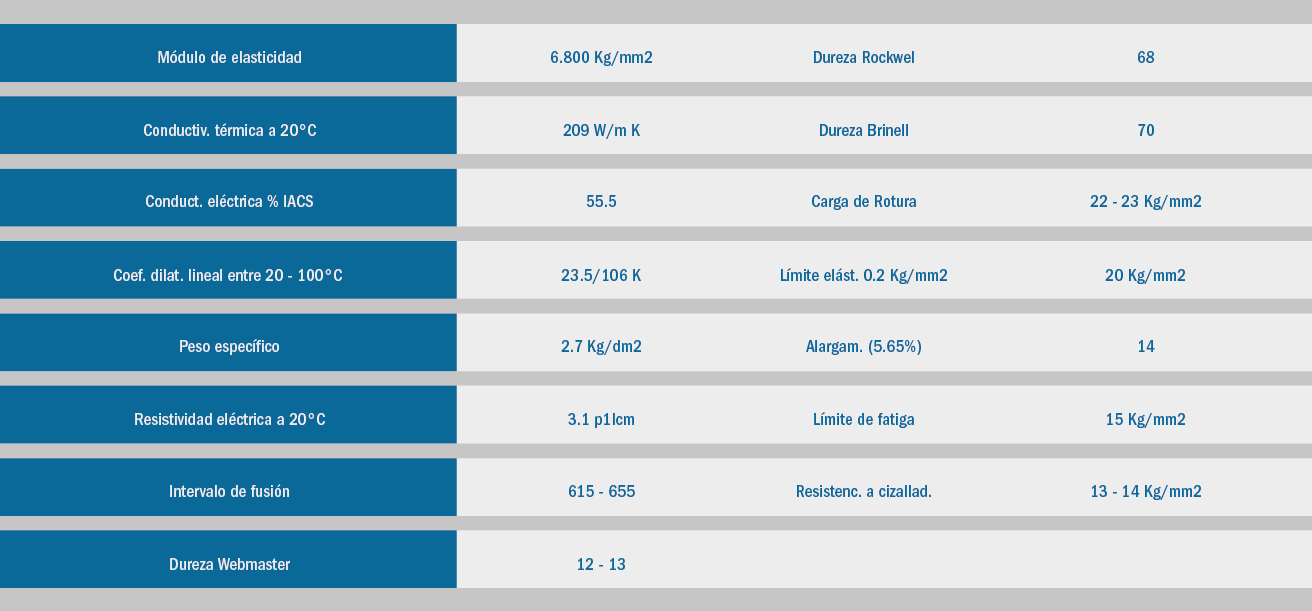

Main physical characteristics of the 6063 alloy in state T5 *:

(*)T5 = Aluminum state after extruded, air cooled and aged at 175 ° C.

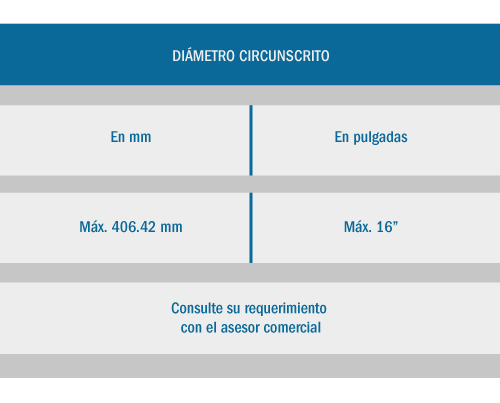

Our maximum diameters of extrusion